Transformation and optimization of urea quantitative open mouth bagging machine

In recent years, with the development of social economy and the progress of science and technology, China's quantitative open mouth bagging machine has been widely used in chemical industry, grain, light industry and other industries. Its extensive application not only improves the automation level in the field of industrial measurement, but also lays a foundation for qualified continuous production of enterprises.

The application of Leadall automation in the quantitative open mouth bagging machine of urea finished products in China has greatly improved the production efficiency of the enterprise, reduced the labor cost and improved the efficiency of the enterprise. But at the same time, through the annual research and analysis of various production data, it is found that the unqualified rate of urea packaging, equipment failure rate and maintenance cost are increasing year by year, and the increasing trend is obvious. Therefore, the research on quantitative packaging technology, improving the packaging accuracy of products, and pursuing the maximization of economic benefits as much as possible on the premise of meeting the requirements of laws and regulations and not affecting the social benefits of enterprises, has always been the key problem that enterprises need to solve, which is also the foothold of this paper.

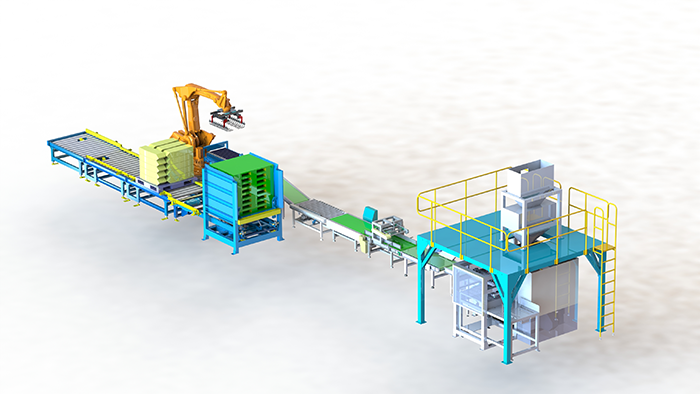

According to the requirements of automatic production of quantitative packaging, on the basis of studying the development and application of relevant technologies at home and abroad, Leadall automation paid attention to analyzing all links of the production process. Firstly, the structure and composition of various quantitative packaging systems are introduced, and the related theories and technologies are deeply understood and studied. Secondly, this paper introduces the composition of the automatic quantitative packaging system of urea and the actual production status of the automatic quantitative packaging system of urea, and then analyzes the specific problems and actual faults of the automatic quantitative packaging system in production, so as to put forward the corresponding solutions and practical improvement measures, and carry out the technical transformation of the quantitative packaging system. In order to complete the research and transformation of quantitative packaging system, its structure and system characteristics must be deeply analyzed in order to provide basis for system design and transformation.

Leadall automation mainly compares and analyzes the characteristics of hardware equipment such as quantitative packaging system, including bag taking unit, weighing unit, pneumatic system and PLC, and studies and improves the PLC control program of the system.

The modified system has good operation effect during the simulation debugging. The results from the actual operation and production data show that 2. The hardware transformation and program improvement of the quantitative packaging system can improve the packaging speed and packaging accuracy, reduce the maintenance workload and maintenance cost, significantly improve the quantitative weighing accuracy, accelerate the weighing speed, and achieve the expected purpose. It is proved that the transformation scheme of urea quantitative packaging system and the implementation scheme are reasonable and effective.